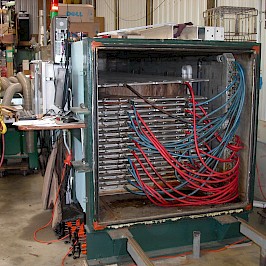

Vacuum Kiln Drying

At John’s Urban Timber, we use advanced vacuum kiln drying to bring reclaimed and salvaged wood to perfect moisture balance while preserving its natural character.

Unlike conventional kilns, our vacuum process gently removes moisture at lower temperatures — reducing stress, cracking, and discoloration. This allows us to dry thicker slabs faster, safer, and more evenly than traditional methods.

All Drying Done In-House — Never Outsourced

Every board and slab is processed on-site at our Whitmore Lake workshop. We don’t send materials elsewhere, ensuring complete control from start to finish.

Our vacuum kiln accommodates a variety of species and thicknesses, making it ideal for live-edge slabs, custom lumber, and reclaimed materials.

Drying times vary based on thickness and species, but most projects reach optimal moisture content in just a few days to weeks — compared months in traditional systems.

We take pride in giving every piece the attention it deserves, so you receive beautifully conditioned wood that’s ready to use right away.

What You Can Expect:

- In-house vacuum kiln drying – Every board is dried under controlled conditions in our own facility.

- Stable drying – Vacuum kiln drying greatly reduces warping, splitting, and internal stress.

- Thick slab capability – Perfect for large, live-edge, and reclaimed wood projects.

- Sustainable process – Low-temperature drying that reduces energy waste and preserves natural color.

Do You Want Vacuum Kiln Drying ? Contact Us Now

Where specialty is normal and unique is everything. My business is providing the services people need to recycle and reclaim wood into useful products, and I have been doing this since the fall of 1998.